Arduino two weel self Balancing Robot

This is a relatively simple, visually effective balancing robot project that only requires four components to make. Detailed video, instructions, schematic, and code at:

Tạo bởi

admin

Khoá học bao gồm:

-

Certificate of completion -

Certificate of completion -

Certificate of completion

Những gì bạn đặt được sau khoá học

Master JavaScript fundamentals including ES6+ features

Master JavaScript fundamentals including ES6+ features

Project description

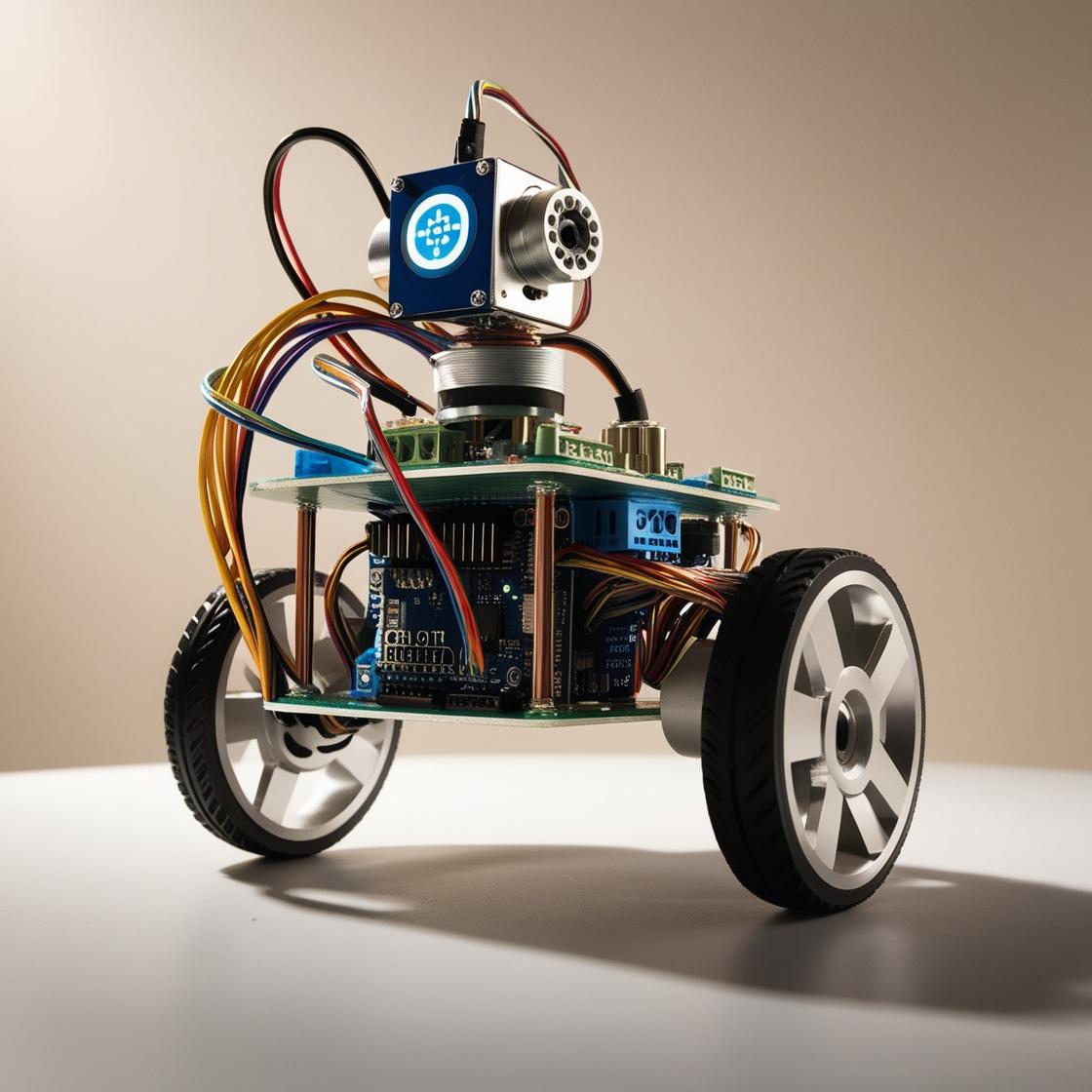

Self Balancing Robot is device that can balance itself from falling to the ground. Its function is to maintain balance using the motor’s axis movement of the wheels and body. There are several types of self-balancing robots, and in this particular case I will present you a way to make a Two-Wheeled Balancing Robot. Actually, I made this robot together with one of my students and it is a high school graduation project. This is the simplest type of balancing robot and only requires a few components to build.

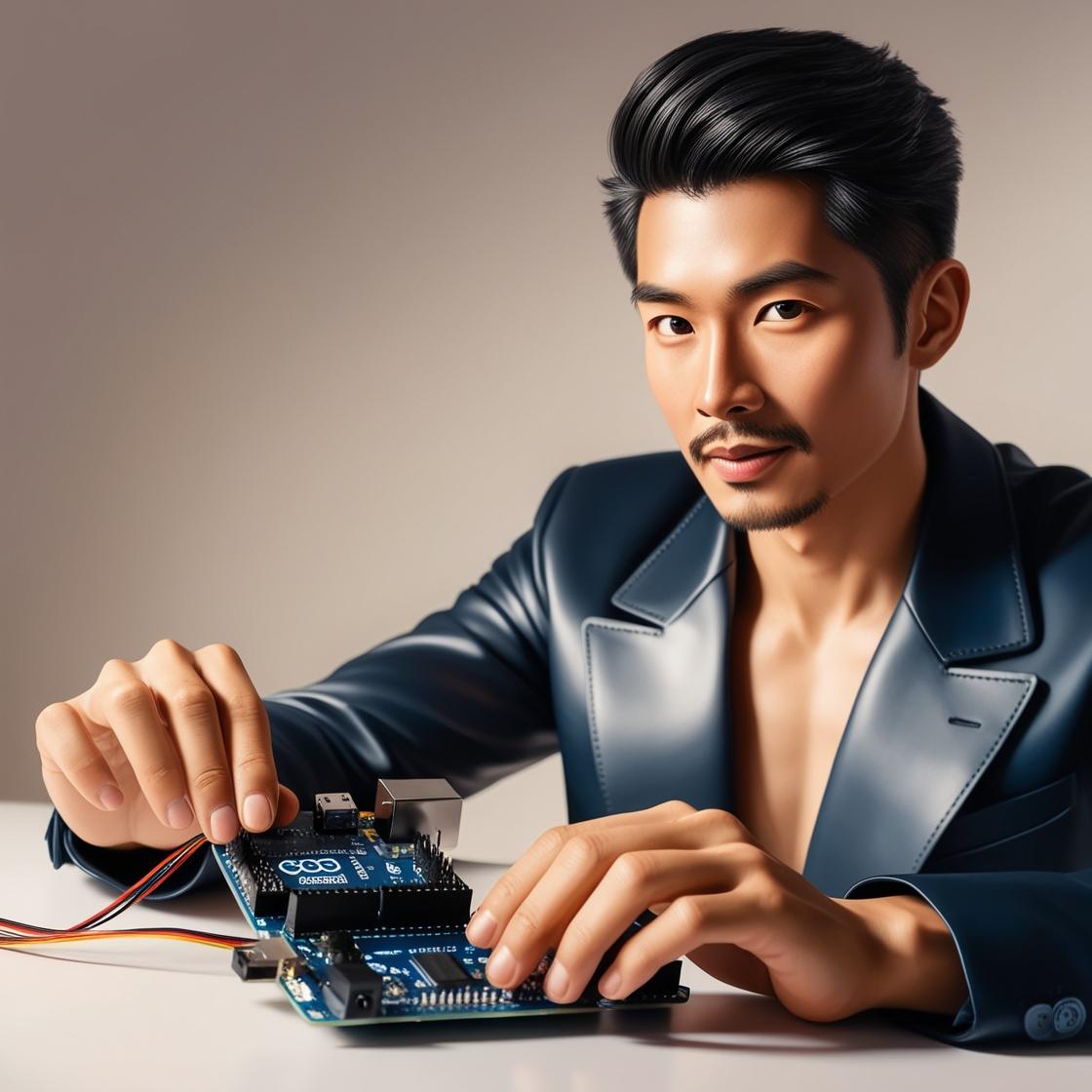

First, let’s explain the components used and their functions.

– MPU6050 Accelerometer and Gyroscope sensor with Micro Electro Mechanical System(MEMS) technology, which is used to detect angle of tilt or inclination along the X, Y and Z axes.

– The information from this sensor is transmitted to a microcontroller, and in our case it is an Arduino Uno board. This board is the brain of the robot, processes the sensor data and determines the actions needed to keep the robot upright.

– Processed data from the Arduino is sent to the motor driver board, which in our case is the L298N 5AD type. A motor driver circuit controls the direction and speed of the motors.

– This robot uses two DC motors, each connected to a wheel. These motors adjust the speed of the wheels to correct the robot’s tilt.

– and power source, specifically two Lithium batteries connected in series wich provides energy to the motors and electronics. All components are mounted on a suitable supporting structure made of 5mm thick PVC board.

To obtain this value, we need to hold the robot in an ideal vertical position, perpendicular to the surface, and read the required value on the serial monitor. In my case, it is about 18 2

Finally, we need to experimentally determine the values of Kp, Kd, and Ki, needed for PID control.

#include "I2Cdev.h"

#include

#include "MPU6050_6Axis_MotionApps20.h" //https://github.com/jrowberg/i2cdevlib/tree/master/Arduino/MPU6050

MPU6050 mpu;

// MPU control/status vars

bool dmpReady = false; // set true if DMP init was successful

uint8_t mpuIntStatus; // holds actual interrupt status byte from MPU

uint8_t devStatus; // return status after each device operation (0 = success, !0 = error)

uint16_t packetSize; // expected DMP packet size (default is 42 bytes)

uint16_t fifoCount; // count of all bytes currently in FIFO

uint8_t fifoBuffer[64]; // FIFO storage buffer

// orientation/motion vars

Quaternion q; // [w, x, y, z] quaternion container

VectorFloat gravity; // [x, y, z] gravity vector

float ypr[3]; // [yaw, pitch, roll] yaw/pitch/roll container and gravity vector

/*********Tune these 4 values for your BOT*********/

double setpoint= 182; //set the value when the bot is perpendicular to ground using serial monitor.

//Read the project documentation on circuitdigest.com to learn how to set these values

double Kp = 15; //21 Set this first

double Kd = 0.9; //0.8 Set this secound

double Ki = 140; //140 Finally set this

/******End of values setting*********/

double input, output;

PID pid(&input, &output, &setpoint, Kp, Ki, Kd, DIRECT);

volatile bool mpuInterrupt = false; // indicates whether MPU interrupt pin has gone high

void dmpDataReady()

{

mpuInterrupt = true;

}

void setup() {

Serial.begin(115200);

// initialize device

Serial.println(F("Initializing I2C devices..."));

mpu.initialize();

// verify connection

Serial.println(F("Testing device connections..."));

Serial.println(mpu.testConnection() ? F("MPU6050 connection successful") : F("MPU6050 connection failed"));

// load and configure the DMP

devStatus = mpu.dmpInitialize();

// supply your own gyro offsets here, scaled for min sensitivity

mpu.setXGyroOffset(-479);

mpu.setYGyroOffset(84);

mpu.setZGyroOffset(15);

mpu.setZAccelOffset(1638);

// make sure it worked (returns 0 if so)

if (devStatus == 0)

{

// turn on the DMP, now that it's ready

Serial.println(F("Enabling DMP..."));

mpu.setDMPEnabled(true);

// enable Arduino interrupt detection

Serial.println(F("Enabling interrupt detection (Arduino external interrupt 0)..."));

attachInterrupt(0, dmpDataReady, RISING);

mpuIntStatus = mpu.getIntStatus();

// set our DMP Ready flag so the main loop() function knows it's okay to use it

Serial.println(F("DMP ready! Waiting for first interrupt..."));

dmpReady = true;

// get expected DMP packet size for later comparison

packetSize = mpu.dmpGetFIFOPacketSize();

//setup PID

pid.SetMode(AUTOMATIC);

pid.SetSampleTime(10);

pid.SetOutputLimits(-255, 255);

}

else

{

// ERROR!

// 1 = initial memory load failed

// 2 = DMP configuration updates failed

// (if it's going to break, usually the code will be 1)

Serial.print(F("DMP Initialization failed (code "));

Serial.print(devStatus);

Serial.println(F(")"));

}

//Initialise the Motor outpu pins

pinMode (6, OUTPUT);

pinMode (9, OUTPUT);

pinMode (10, OUTPUT);

pinMode (11, OUTPUT);

//By default turn off both the motors

analogWrite(6,LOW);

analogWrite(9,LOW);

analogWrite(10,LOW);

analogWrite(11,LOW);

}

void loop() {

// if programming failed, don't try to do anything

if (!dmpReady) return;

// wait for MPU interrupt or extra packet(s) available

while (!mpuInterrupt && fifoCount < packetSize)

{

//no mpu data - performing PID calculations and output to motors

pid.Compute();

//Print the value of Input and Output on serial monitor to check how it is working.

Serial.print(input); Serial.print(" =>"); Serial.println(output);

if (input>150 && input<200){//If the Bot is falling

if (output>0) //Falling towards front

Forward(); //Rotate the wheels forward

else if (output<0) //Falling towards back

Reverse(); //Rotate the wheels backward

}

else //If Bot not falling

Stop(); //Hold the wheels still

}

// reset interrupt flag and get INT_STATUS byte

mpuInterrupt = false;

mpuIntStatus = mpu.getIntStatus();

// get current FIFO count

fifoCount = mpu.getFIFOCount();

// check for overflow (this should never happen unless our code is too inefficient)

if ((mpuIntStatus & 0x10) || fifoCount == 1024)

{

// reset so we can continue cleanly

mpu.resetFIFO();

Serial.println(F("FIFO overflow!"));

// otherwise, check for DMP data ready interrupt (this should happen frequently)

}

else if (mpuIntStatus & 0x02)

{

// wait for correct available data length, should be a VERY short wait

while (fifoCount < packetSize) fifoCount = mpu.getFIFOCount();

// read a packet from FIFO

mpu.getFIFOBytes(fifoBuffer, packetSize);

// track FIFO count here in case there is > 1 packet available

// (this lets us immediately read more without waiting for an interrupt)

fifoCount -= packetSize;

mpu.dmpGetQuaternion(&q, fifoBuffer); //get value for q

mpu.dmpGetGravity(&gravity, &q); //get value for gravity

mpu.dmpGetYawPitchRoll(ypr, &q, &gravity); //get value for ypr

input = ypr[1] * 180/M_PI + 180;

}

}

void Forward() //Code to rotate the wheel forward

{

analogWrite(6,output);

analogWrite(9,0);

analogWrite(10,output);

analogWrite(11,0);

Serial.print("F"); //Debugging information

}

void Reverse() //Code to rotate the wheel Backward

{

analogWrite(6,0);

analogWrite(9,output*-1);

analogWrite(10,0);

analogWrite(11,output*-1);

Serial.print("R");

}

void Stop() //Code to stop both the wheels

{

analogWrite(6,0);

analogWrite(9,0);

analogWrite(10,0);

analogWrite(11,0);

Serial.print("S");

}

For this purpose we set all three values to zero. Now we put some value for Kp and perform testing. Too little Kp will make robot fall over. Too much Kp will make the robot go back and forth wildly. A good Kp will make the robot go slightly back and forth. Next we need to set Kd. A gooD Kd value will lessen the oscilation until the robot is almost steady, and will keep the robot standing. Lastly set the Ki. The correct Ki value will shorten the time it takes for the robot to stabilize. I want to emphasize that the surface needs to be rough enough to increase the friction between it and the wheels.

And finally a short conclusion. This is a relatively simple, visually effective balancing robot project that only requires 3 components to make. However, its setup, although it can be time-consuming, is still a lot of fun trying to get the robot to stand steadily on its “own feet”. Just to mention that we created this project together with my students as a final high school exam.

Giáo trình

Course Overview

4 bài giảng . 20 phút

Introduction to the Course

10:30

Introduction to the Course

Introduction to the Course

10:30

Introduction to the Course

Introduction to the Course

10:30

Introduction to the Course

Introduction to the Course

10:30

Introduction to the Course

Requirements

- Basic understanding of HTML and CSS

- Basic understanding of HTML and CSS

- Basic understanding of HTML and CSS

Instructor

Gia Huy

Senior JavaScript Developer & Educator

David has been working with JavaScript for over 10 years and has taught more than 50,000 students online. He currently works as a senior developer at a leading tech company and is passionate about sharing his knowledge with others. His teaching style focuses on practical, real-world applications of JavaScript concepts, ensuring students not only understand the theory but can apply it in their own projects.

Frequently Asked Questions

Warning: Undefined array key "q" in /home/xs693666/ichidemo.info/public_html/demo2.ichidemo.info/wp-content/themes/innovators/single-course.php on line 340

Warning: Undefined array key "a" in /home/xs693666/ichidemo.info/public_html/demo2.ichidemo.info/wp-content/themes/innovators/single-course.php on line 346

Warning: Undefined array key "q" in /home/xs693666/ichidemo.info/public_html/demo2.ichidemo.info/wp-content/themes/innovators/single-course.php on line 340

Warning: Undefined array key "a" in /home/xs693666/ichidemo.info/public_html/demo2.ichidemo.info/wp-content/themes/innovators/single-course.php on line 346

Ready to Master JavaScript?

Join over 18,000 students who have transformed their careers with this comprehensive JavaScript course.